Presence and Orientation of IC Chips Seated in Nests

The compact LM laser measurement sensor reliably inspects multiple statuses with one compact device

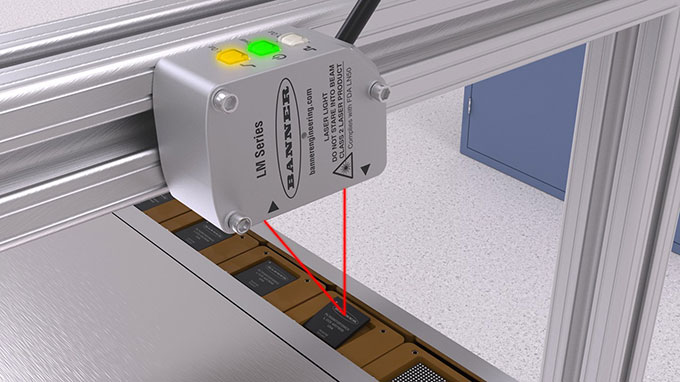

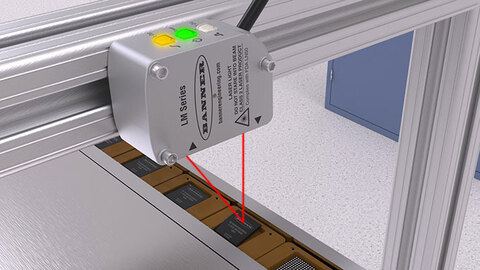

Integrated circuit (IC) chips must be seated entirely and right side up in nests for presentation to a test station. Due to the small size of the targets, a precise measurement solution is required to ensure that each chip is present and oriented correctly in each nest. The LM laser measurement sensor solves this challenging application.

In semiconductor manufacturing, integrated circuit chips are tested one at a time for functionality and performance. The IC chips are placed in a nest and then delivered to the test station. And, to finish the test processes correctly, the chips must be completely seated and right side up in the nests.

There are several common failure modes in this application: no chip in a nest, one chip tilted in the nest (creating a small height difference), two chips stacked in one nest, and a chip upside down in the nest. Multiple sensors are often required to identify these failures. However, test stations do not have space for large vision systems or many sensors. Also, the nests of chips move quickly, which can be difficult for many sensors to track. A quick measurement solution is needed to ensure optimal machine throughput.

The LM laser distance sensor reliably inspects multiple conditions with one compact device and can verify both chip presence and orientation. Besides, with a 4 kHz (0.25 ms) sampling rate, the LM can reliably solve this high-speed application with fast-moving targets.

Your Benefits

- Reduction of sensor and maintenance expenditures due to the featured variety

- Greater precision during IC chip inspection thanks to a resolution of 0.004 mm and linearity of +/-0.06 mm

- Reliable checks despite ambient temperature fluctuations

- Industria Auto

- Body Detection in Automobile Production

- Motor Control with Condition Monitoring

- IP67 Hybrid Module Processes Safety Signals

- Decentralized monitoring of cooling stations

- Roboterschweißzellen mit Ethernet vernetzt

- Monitoring the cooling circuit on welding clamps

- Flow monitoring in drum washers

- Măsurarea grosimii foilor de tablă

- Monitorizarea stării motoarelor

- Cloud-based level monitoring

- Secția de presaj - Presă de metal cu identificare de unelte

- Secția de caroserii - Detecția piulițelor de sudură

- Vopsitorie - Identificare patine de ghidaj

- Asamblarea finală - Montarea geamurilor cu ajutorul robotului

- Sistem de propulsie - Verificare fără contact a paleților de transport

- Secţie caroserie – Zona de protecţie pentru celule robotizate

- Item-level Detection with UHF RFID

- Supply of cooling lubricant in machine tools

- Controlling hydraulic pressure in pressing plants

- Measuring process pressure on scissor lifts

- Secţie caroserie – Inspecţia vârfului de sudură în industria auto

- Alimentare manuală în celula de sudură

- Asamblarea finală – Detectarea componentelor negre pe panoul negru al uşii

- Detecţie trapă sticlă transparentă

- Inspecţii la distanţă mare folosite la asamblarea automobilelor

- Detecţia garniturii de cauciuc la blocul motor

- Sistem de propulsie – Detecţie montare corectă a pieselor din blocul motor

- Detecţie vehicul electric

- Detectarea vehiculului într-o spălătorie cu autoservire

- POVEŞTI DE SUCCES

- Decentralized Safety Technology for Modular Production

- Modular Conveyor System

- RFID şi module I/O pentru schimbarea sigură a uneltelor

- Ghidaje RFID pentru AGV în producţia de suspensii

- Producţia de tobe de eşapament folosind IO-Link

- Identificarea suportului de piese în producţia de componente de ventilaţie

- Detecţia piuliţei de sudură

- Trasabilitate cu RFID

- RFID în producţia de motoare

- Producţie de bare cu Identificare

- Soluţii pentru vopsitorii

- Senzori pentru sudură şi asamblare

- Senzori Poziţie Unghiulară pentru Sisteme de Asamblare

- Identificarea uneltelor

- Pick-to-light pentru asamblarea de amortizoare

- Identificare cu RFID a duzelor de injecţie

- RFID în secţia caroserii

- IO-Link simplifică producţia de angrenaje diferenţiale

- Industria chimică

- Ethernet Signal Connection in the I&C Room

- Ethernet-based Automation of Modular Skids

- Ex Isolation in Modular Process Plants

- Detection of Pigs

- Semnal I/O la distanţă

- Easy Connection of Field Devices

- Procesarea semnalului cu sistem I/O în tabloul electric

- Separarea semnalului prin tehnologia interfeţei în tabloul electric

- Identificarea racordurilor de furtun

- Monitorizarea eficientă a tablourilor electrice în câmp

- Monitorizarea actuatoarelor sfert de tură

- Planificarea şi asamblarea soluţiilor pentru sisteme

- Povești de Succes

- I/O System Excom Creates Space in the I&C Rooms

- RFID în zonele 2 şi 22

- Controlul eficient al testării

- Comunicaţie de câmp cu protecţie intrinsecă

- Parteneriat sistem control proces

- I/O la distanţă în Zonă cu Risc de Explozie

- Confirmare poziţie valvă duală

- Flexibilitate cu fieldbus

- Administrare patrimoniu cu I/O la distanţă

- Poziţionarea corectă cu RFID în producţia de carbid

- Fast conversion in restricted space

- Energie

- Industria Alimentară și a Băuturilor

- Condition Monitoring of Control Cabinets

- Condition Monitoring in Storage Rooms

- Controlul grosimii aluatului în maşinile de rulat

- Identificarea containerelor alimentare

- Verificarea recipientelor

- Detecţia poziţiei valvelor

- Detectare poziţie țevi de racord

- Identificarea matriţelor pentru ciocolată

- Povești de Succes

- Decentralized Control Modules in Coldstore

- Urmărire şi identificare cu RFID în producţia de carne

- Encoder fără contact în producţia de cartofi

- UHF RFID în centrul de distribuţie alimentară

- RFID pentru producţia de ciocolată

- I/O distribuit pentru echipamente alimentare

- I/O la distanţă pentru distilerii

- RFID şi autoclave

- Transparenţă în producerea ciocolatei

- Surse de alimentare IP67 pentru conveiere

- Identificare în depozitarea produselor alimentare

- Detecţia recipientelor cu cameră

- Logistică

- Decentralized Muting of Electro-sensitive Protectice Equipment

- I/O Blocks Control Roller Conveyor Modules

- Fast Tag Detection at Warehouse Gates

- Item-level Detection with UHF RFID

- Întreținerea preventivă a benzilor transportoare

- Detection of Transport Containers

- Level Detection in Vessels

- Identification of Cryovessels

- Identification of Mobile Containers with Handheld Devices

- Identification of Food Containers

- Tier 1 – Bumper Identification

- Condition Monitoring in Storage Rooms

- Collision Protection on Reach Stackers

- Success Stories

- Contact-free Encoder in Potato Production

- Decentralized Control Modules in Coldstore

- Speed Control via Radar Sensor QT50

- IP67 Power Supplies for Conveyors

- Modular Conveyor System

- RFID Solution for Warehouse

- RFID Guides AGV in Suspension Production

- RFID Identifies Pharmaceuticals

- UHF RFID in Food Distribution Center

- Echipamente Mobile

- Automatic Slope Compensation

- Distribution Lines for Field Sprayers

- Angle Measurement on a Field Sprayer

- Monitorizarea fluxului de materiale în combină

- Determinarea poziţiei unghiulare a braţului macaralei

- Iluminarea compartimentului de echipamente al maşinilor de pompieri

- Măsurare pe două axe a înclinării unei combine

- Collision Protection on Reach Stackers

- Povești de Succes

- Selective Asparagus Harvester

- Măsurarea poziţiei cu RFID şi Encoder

- Speed Control via Radar Sensor QT50

- RFID Guides AGV in Suspension Production

- Block I/O Modules on Super Yacht

- Encoder fără uzură pe drage purtătoare

- I/O pentru suprimarea prafului

- Răcire tablou

- Conectică Quick-Disconnect

- Soluţii de automatizare pentru frig extrem

- I/O la distanţă pentru macarale

- Elevator robust de metale grele

- Poziţionare montagnes russes

- Soluţii pentru utilaje mobile

- Poziţionare la înălţimea exactă

- Detecţia unghiului critic

- Senzor de poziţie unghiulară detectează ridicarea platformei

- Petrol și gaze

- Industria de împachetare

- Decentralized RFID Package Verification

- Identificarea cartuşelor de imprimare color

- Funcţionarea sigură a maşinilor

- Verificarea recipientelor

- Monitorizarea capacelor pe liniile de îmbuteliere

- Monitorizarea proceselor de schimbare a formatului

- Identificarea sticlelor de test

- Monitorizarea nivelului cafelei măcinate

- Level Detection in Vessels

- Detection of Transport Containers

- Povești de Succes

- Industria farmaceutică

- Decentralized package verification for pharmaceutical products

- Automate Modular Skids

- Pharmaceutical Skids with Decentralized I/O Technology

- Ex Isolation in Modular Process Plants

- Control of Valve Interfaces

- Monitorizarea actuatoarelor sfert de tură

- Detectare poziție racord

- Semnal I/O la distanță

- Planificarea și construirea sistemelor Super Skid

- Conectarea ușoară a dispozitivelor de câmp

- Identificarea recipientelor criogenice

- Identificarea containerelor mobile

- Identificarea containerelor mobile cu dispozitive portabile

- Identificarea racordurilor de furtun pentru precursori

- Identificarea racordurilor de furtun în zone sterile

- Identificarea racordurilor de furtun în Zona 1 Ex

- Identificarea sacilor mari şi a bioreactoarelor

- Identification of Single-Use Applications

- POVEȘTI DE SUCCES

- Transferul fără contact al energiei şi al semnalelor în comutaţie

- Control HMI pentru blender industrial

- Gateway-ul BL20 programabil cu CodeSys controlează mașina de procesare imagini

- RFID identifică produse farmaceutice

- Speed measurement of mixing heads in magnetic stirrers

- Reading Device Detects Different Materials

- Semiconductori

Select Country

Turck worldwide